5 Material Innovations to Slash Concrete's Carbon Footprint

Without a doubt, concrete is one of the most ubiquitous materials of modern construction -- if not the post-industrial chapter of our history. The strength and versatility of concrete, also known as the ordinary Portland cement, have revolutionized construction, allowing us to build everything from towering skyscrapers to sprawling infrastructure, all with a readily available and relatively easy-to-use material.

Nevertheless, the production of cement is a major culprit behind climate change, responsible for roughly 8 percent of global carbon dioxide emissions, or a staggering 2.5 billion tones annually. This process involves heating massive kilns, stretching the length of two football fields, to incredibly high temperatures reaching 1,500°C, or about 2,732°F.

To address this growing concern, the construction industry urgently needs sustainable alternatives and material innovations to create a lower-carbon concrete future. But luckily, low-carbon solutions are emerging.

Rethinking the Glue: Carbon-Neutral Cement Alternatives

One promising approach lies in replacing or reducing reliance on Portland cement with alternative binders. Geopolymers, for instance, are activated by alkali solutions and can utilize industrial byproducts like fly ash, derived of coal combustion, and slag, a residue of steel production. These offer comparable strength to Portland cement but boast a much lower carbon footprint during production.

Another avenue is calcined clays. These clays undergo a high- temperature calcination process, resulting in a low-carbon cement alternative with good binding properties. We can also leverage existing industrial byproducts. Supplementary cementitious materials (SCMs) can be blended with Portland cement. This reduces the overall content of clinker, the most carbon-intensive component of traditional cement, leading to a significant decrease in CO2 emissions.

The search continues for even more sustainable options. Bio-based materials are being explored for their potential as future binders or additives in concrete. These materials offer the exciting possibility of not only reducing reliance on traditional cement but also capturing carbon within the concrete itself.

Building with Scraps: Recycled Aggregates and Waste-Derived Materials

Concrete is a hungry beast, demanding vast quantities of coarse and fine aggregates – crushed rock, sand, and gravel. Traditionally, these materials have been sourced from virgin quarries, leading to environmental concerns and depletion of natural resources. Thankfully, innovative approaches are turning waste into opportunity by incorporating recycled aggregates and waste-derived materials into concrete mixtures.

One key player is recycled concrete aggregate (RCA). Construction and demolition debris are crushed and processed, offering a sustainable alternative to virgin aggregates. This not only reduces the demand for quarrying but also diverts waste from landfills, creating a closed-loop system for concrete materials.

The possibilities extend beyond concrete itself. Crushed glass and ceramic waste from demolition projects are finding new life as coarse aggregates in concrete mixes. These recycled materials offer several advantages, including improved thermal insulation and even aesthetic benefits in exposed concrete applications. Industrial byproducts are also joining the mix.

Certain processes generate materials with suitable properties for use as aggregates. This not only diverts waste but can also offer additional benefits in the concrete mix. For instance, some byproducts can improve workability or even enhance fire resistance.

Capturing Carbon, Strengthening Concrete: CCU Technologies

The fight against climate change demands innovative solutions across all industries, and construction is no exception. Although the evidence varies, Carbon Capture and Utilization (CCU) technologies offer a game- changing approach to tackling concrete's carbon footprint. They capture carbon dioxide emissions from industrial processes, preventing them from entering the atmosphere. But instead of simply storing the captured CO2, CCU transforms it into valuable products, creating a closed-loop system that benefits both the environment and construction practices.

One particularly exciting application of CCU in concrete production is CO2-cured concrete. This innovative technique utilizes captured carbon dioxide to accelerate the natural carbonation process within the concrete mix. The captured CO2 reacts with the calcium hydroxide in the concrete, not only enhancing its strength and durability but also permanently sequestering the carbon dioxide within the material itself. This translates to a double benefit – a more robust concrete and a significant reduction in overall CO2 emissions.

Nature's Touch: Bio-based Additives in Concrete

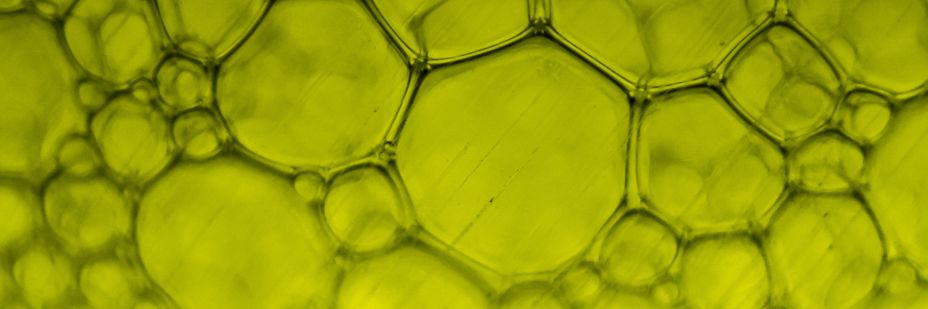

Concrete isn't just about rock and cement anymore. Researchers are exploring the potential of bio-based additives and eco-friendly admixtures derived from renewable sources like agricultural residues, biopolymers, and even algae. These innovative materials offer a multitude of benefits.

For instance, bio-based additives can improve the workability of fresh concrete, making it easier to place and mold. Additionally, they can reduce the overall water demand in concrete mixes, leading to a more sustainable production process.

Perhaps even more excitingly, some bio-based additives hold the potential to enhance concrete's ability to sequester carbon dioxide, further reducing its environmental footprint.

Beyond Green Dreams: High-Performance Sustainable Concrete

The future of concrete isn't just about being eco-friendly; it's about achieving peak performance with a minimized environmental impact. Researchers are developing high-performance sustainable concrete mixtures that combine multiple innovations.

Pioneering concrete blends can now combine carbon-neutral binders, recycled aggregates, and bio- based additives for a truly sustainable mix. These advanced formulations deliver impressive structural performance and durability, meeting the rigorous demands of modern construction.

The benefits extend beyond the initial construction phase. Sustainable concrete boasts a significantly lower life-cycle carbon footprint, making it a compelling choice for buildings, infrastructure projects, pavements, and precast elements.

Life-cycle assessments (LCA) and green building certifications like LEED, BREEAM or Green Stars ensure the environmental benefits of sustainable concrete are measured and rewarded. This incentivizes wider adoption of these high-performance, eco-friendly mixtures.

Building a Sustainable Future: Policy and Market Forces

Innovation alone can't ensure a greener future for concrete. Supportive policies, regulations, and market incentives are crucial for widespread adoption of these sustainable solutions. Government initiatives that encourage investment in low-carbon concrete technology development can accelerate innovation and bring these technologies to market faster.

Additionally, regulations that prioritize the use of sustainable construction materials in public projects can set a powerful example and stimulate demand throughout the industry.

The future of concrete is green. Innovation in materials, from low-carbon binders to recycled aggregates, coupled with supportive policies and market demand, can significantly reduce concrete's environmental impact. High-performance sustainable mixtures offer strength and eco- friendliness, paving the way for a greener construction industry, one project at a time.